|

Who’s Minding the

Farm?: Precision Agriculture, Yield Mapping and Site-specific Farming |

Further Understanding Spatial Patterns and Relationships ( |

Feature article for GeoWorld,

February 1998, Vol. 11, No. 2, pgs. 46-51

<Click here> right-click for a

printer-friendly version of this paper (.pdf).

Who’s Minding the Farm? (Part 1)

Precision Farming Modernizes Conventional Techniques

(Part 2)

Yield Mapping

Who’s Minding the Farm?: Precision Agriculture, Yield

Mapping and Site-specific Farming

(Part 1) by Joseph K Berry

(Part 1) by Joseph K Berry

Big changes are

underway in agriculture, thanks to GIS and related spatial technologies. As a result, farmers are reaping cost savings

and production increases as well as improved stewardship and environmental

benefits.

Introduction

To many, precision farming seems like an oxymoron. With mud

up to the axles and 400 acres left to plough, precision seems worlds away. Yet site-specific

management makes sense to a rapidly growing number of farmers. Mapping and

analyzing variability in field conditions, and linking such spatial

relationships to management action, places production agriculture at the

cutting edge of GIS applications.

Underlying

Principles

Until the 1990s, maps played a minor role in production

agriculture. Most soil maps and topographic sheets were too generalized to

apply at the farm level. As a result, the principle of whole-field management

based on broad averages of field data, dominated management actions.

Weigh-wagon and grain elevator measurements established a field's yield

performance, and soil sampling determined the typical nutrient levels within a

field. Farmers used such data to determine best overall seed varieties,

fertilization rates and a bushel of other decisions-all treating an entire

field as a uniform whole within its boundaries.

Site-specific management, on the other hand, recognizes the

variability within a field and involves doing the right thing, in the right

way, at the right place and at the right time. The approach involves assessing

and reacting to field variability by tailoring management actions-including

fertilization levels, seeding rates and selection variety-to match changing field

conditions. It assumes that managing field variability leads to cost savings

and production increases as well as improved stewardship and environmental

benefits.

Blending

Technologies

Site-specific farming isn't just a bunch of pretty maps;

it's a set of new technologies and procedures linking mapped variables to

appropriate management actions. Such procedures integrate several key elements:

the Global Positioning System (GPS), on-the-fly data collection devices, GIS

and variable rate implements.

Modern GPS receivers can establish positions within a field

to about a meter. When connected to a data collection device, such as a

yield/moisture meter, these data can be "stamped" with geographic

coordinates. Several portable "heads-up" digitizing devices allow

farmers to sketch conditions, such as weed infestations, on a map or aerial

photo backdrop. GIS maps the field data so a farmer can see the conditions

throughout a field. GIS also can be used to extend yield visualization to

analyzing relationships among yield variability and field conditions.

Once established, these relationships derive a

"prescription" map of management actions required for each location

in a field. The final element, variable rate implements, notes a tractor's

position through GPS, continuously locates it on the prescription map, then

varies the application rate of field inputs, such as fertilizer blend or seed

spacing, according to precise instructions for each location. Combining

technologies such as GPS, GIS and intelligent devices and implements provides

the mechanisms to manage field variability. The maturation and

commercialization of these technologies have made the concept practical.

Data Processing

To date, most analysis involved visual interpretations of yield

maps. By viewing a map, potential relationships between yield variability and

field conditions spring to mind. These "visceral visions" and

explanations can be drawn through the viewer's knowledge of the field. More

recently, data visualization is being extended through map analysis at three

levels: cognitive, analysis and synthesis.

Precision farming's foundation occurs at the cognitive

level, where desktop mapping is used to manage and store mapped data. At the

analysis level, map analysis is used to discover relationships among variables

such as yield and soil nutrient levels. This step is analogous to a farmer's

visceral visions of relationships, but uses the computer to establish more

detailed mathematical and statistical connections. Although this step is

somewhat an uncomfortable "leap of scientific faith," it extends data

visualization by investigating the coincidence of the variation patterns among

map sets. The results relate yield goals to specific levels of farm

inputs-traditional agricultural research, but tailored to a farmer's

"backyard."

The synthesis level evaluates newly derived relationships

to formulate management action. The result is a prescription map used to guide

the intelligent implements as they "variable rate control" the application

of field inputs. Or the analysis might discover an area of abnormally low yield

as linked with a section of old drainage tile in need of repair. Further

analysis might locate areas in which simulated yield increases under drier

conditions justify the installation of additional drainage tiles.

Technical Issues

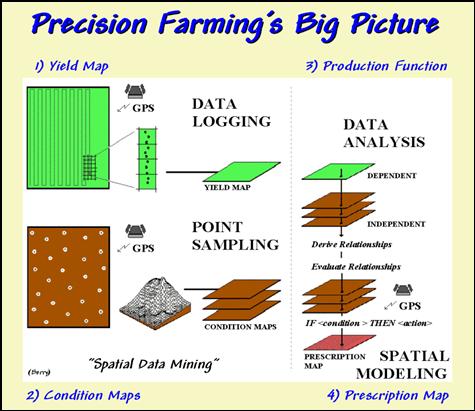

The precision farming process can be broken into four

steps: data logging, point sampling, data analysis and spatial modeling (see figure

1). Data logging continuously records measurements, such as crop yield, as a

tractor moves through a field. Point sampling, on the other hand, uses a set of

dispersed samples to characterize field conditions (e.g., phosphorous,

potassium and nitrogen levels). The data derived by the two approaches are

radically different- a "direct census" of yield that consists of

thousands of on-the-fly samples vs. a "statistical estimate" of the

geographic distribution of soil nutrients based on a handful of soil samples.

Figure 1. The precision farming process can be broken

into four steps: data logging, point sampling, data analysis and spatial

modeling.

In data logging, issues of accurate measurement, such as

GPS positioning and material flow adjustments, are major concerns. Most systems

query the GPS and yield monitor every second, which at 4mph translates into

about six feet. With differential positioning, the coordinates are accurate to

about a meter. But the paired yield measurement is for a location well behind

the harvester, because it takes several seconds for material to pass from the

point of harvest to the yield monitor. To complicate matters, the mass flow and

speed of the harvester change constantly as different terrain and crop

conditions are encountered. The precise placement of GPS/yield records aren't

reflected as much in the accuracy of the GPS receiver as in "smart"

yield mapping software.

In point sampling, users are concerned about surface

modeling issues (estimating between sample points) such as sampling

frequency/pattern and interpolation technique. The cost of soil lab analysis

dictates "smart sampling" techniques based on terrain and previous

data to balance spatial variability with a farmer's budget. In addition,

techniques for evaluating alternative interpolation techniques and selecting

the "best" map using residual analysis are available in some soil

mapping systems.

In data logging and point sampling, the resolution of the

analysis grid used to geographically summarize the data is a critical concern.

Like a stockbroker's analysis of financial markets, the fluctuations of

individual records must be "smoothed" to produce useful trends. If

the analysis grid is too coarse, information is lost in the aggregation across

large grid spaces; if too small, spurious measurement and positioning errors

dominate the information.

The technical issues surrounding mapped data analysis

involve the validity of applying traditional statistical techniques to spatial

data. For example, regression analysis of field plots has been used for years

to derive crop production functions, such as corn yield (dependent variable)

vs. potassium levels (independent variable). A GIS allows users to regress an

entire map of corn yield on a map of soil nutrients to derive the production

function relating the mapped variables. But should you? Technical concerns,

such as variable independence and autocorrelation, have yet to be thoroughly

addressed. Statistical measures assessing results of the analysis, such as a

spatially responsive correlation coefficient, await discovery and acceptance by

the statistical community, let alone the farm community.

In theory, spatial modeling evaluates the relationships

established during the data analysis phase to determine "optimal"

actions, such as the blend of phosphorous, potassium and nitrogen to be applied

at each location in the field. In current practice, these translations are

based on existing science and experience without a direct link to data analysis

of on-farm data. For example, a prescription map for fertilization is

constructed by noting the existing nutrient levels (condition) then assigning a

blend of additional nutrients (action) tailored for each location-an "If (Condition) Then (Action)" set

of rules. The issues surrounding spatial modeling are similar to data analysis

and involve the validity of using traditional "goal-seeking"

techniques, such as linear programming or genetic modeling, to generate maps of

optimal actions.

Current and future

directions

GIS has evolved rapidly within production agriculture. In

less than 10 years the application has moved from inception to operational

reality. Its current expression emphasizes the generation of yield maps by

linking GPS with on-the-fly yield monitors. Valuable insight is gained by

visualizing field variability, particularly when yield maps for several years

are considered. More advanced applications involve analyzing soil nutrient maps

to derive a prescription map used in variable rate fertilizer control.

The infrastructure for precision farming is in place. Most

manufacturers offer precision farming options with their vehicles and

implements and a growing cadre of service providers offers advice to farmers

interested in adopting the new technology. Opportunities abound in one of GIS'

more important applications and, quite literally, we'll all benefit from its

fruits.

Precision Farming Modernizes Conventional Techniques

(Part 2) by Grant Mangold

(Part 2) by Grant Mangold

Tracing the effect of site-specific farm management requires a look at

where the industry has been, where it is and where it's headed. Harnessing the

technologies that make precision farming possible promises to empower farmers

to meet the economic and ecologic objectives of their farm businesses.

Site-Specific Managers

When Adam and Eve first picked up a hoe in the Garden of Eden, they

practiced site-specific agriculture—planting seeds, nurturing the seeds and

harvesting the yields. With an innate desire to know and to do, mankind has

progressed past placing a dead fish in every hill of corn, beans and squash.

Now when a farmer or rancher reaches into a toolbox, he or she finds bits and

bytes and satellite parts along with socket sets and drill bits. Computers

connect to combines and crop input applicators driven by geo-referenced data

processed through GIS applications.

Such technologies make sense to modern agricultural producers, many of

whom have spent their careers carefully managing family farms that go back

generations. At the heart of precision farming lies site-specific management,

which involves the ability to collect and control information to accurately and

appropriately address parts of fields for actual needs, rather than whole

fields for average needs. Site-specific managers use information technologies

to turn their data into decisions.

Such farmers follow a precise process, acquiring raw data, analyzing

derived information, adding related knowledge and applying the results with

wisdom. They depend on precise devices to deliver precise data to determine

precise advice. This requires them to inventory practical variability within

their fields, investigate probable causes, instigate possible solutions to

address management opportunities on a site-specific basis and evaluate the

whole process. Farmers finally have tools for real time, on-farm research. As a

result, they have the potential to produce food and fiber more efficiently.

Current Capabilities

Precision farming allows today's agricultural producers, advisors and

researchers to integrate information technologies with numerous field and

office activities. Such tools include GIS, the Global Positioning System,

remote sensing, on-the-go sensors, monitors and controllers. For example, it's

possible today to meter out multiple crop-protection products to specific sites

through irrigation systems and applicators with on-the-go sensors as well as

track yield and crop quality with growth simulation software, sensors and

remote imaging. Data collected remotely or on-site can be sent via new

telecommunication capabilities for near real-time analysis. As a result,

farmers now have new tools to predict the outcome of site-specific

management--weather permitting.

But how many farmers actually use these new technologies? There are

about 300 million cropland acres in the

Yield monitoring appears to be the most extensive site-specific farming

technology. A recent @gInnovator survey of nearly 20 yield monitor

manufacturers estimates 17,000 on-the-go units were used for harvesting North

American crops in 1997. That figure is up from 10,000 in 1996, 4,400 in 1995,

1,200 in 1994, 300 in 1993 and about 50 in 1992. Worldwide, there are perhaps

20,000 on-the-go yield monitors. That's about 3% of the world's combines. About

half have GPS capabilities, so the data collected can be turned into maps--a

rising trend.

Figure 2. Of the approximately 340,000 farmers with

more than $100,000 in annual sales, almost 50% use computers for farm business,

and 20% have Internet access.

(Courtesy of LEXION Combine Division)

If you figure 1,500 acres per monitor (as some manufacturers suggest),

or perhaps 25.5 million acres, this would be about 8% of

Currently, the acreage under site-specific or variable-rate input

application likely runs less than half the yield monitoring figure.

The 1997 Precision Agriculture Dealership Survey, conducted by Farm

Chemicals magazine and Purdue University, indicates one-third of U.S.

agrichemical dealers sampled in the nationwide survey offer soil sampling with

GPS, and more than 40% perform field mapping. Some 25% provide yield mapping

analysis, 15% handle yield monitor sales and support, 29% offer agronomic

interpretation of GPS data, 80% sell seed and 51% sell enhanced seed. Almost 5%

can perform variable rate seeding, 84% offer custom application services and

50% provide variable rate application. Such figures lead one to project an

increase in site-specific services.

Site-specific management drives farmers to accurate record keeping,

which will direct their decisions. This must be the next transition: from

precision farming to appropriate agriculture--doing the right thing at the

right time in the right place in the right way. Today, the payoff appears to be

in the process, rather than in off-the-shelf precision farming products. The

economics of the practices are site-specific. What farmers need is

"precise advice," which will be determined through more research by

farmers, suppliers and universities.

Focusing on the Future

Future farmers will be plugged

into the planet as never before. They'll use conduits of digital information,

piping data to and from their farm fields. They'll connect with channels of

electronic communication, as they forge new links in the farm-to-food chain.

And they'll work in new ways with new communities of suppliers and customers.

Behind every technology is a philosophy. Most farmers adopting site

specific technologies do so to discover ways to cut their costs, to use inputs

appropriate to the productive capacity of the site, and to optimize their

outputs for a safe and stable supply of food and fiber.

They're not just "farming by the numbers," but they are able

to apply more science to the art of farming. They don't want to become

entrapped by data-driven technologies; they expect to be empowered with

decision making tools. Farmers are more like artists than accountants. Sure,

they watch the bottom line. But producing a crop puts all their knowledge and

wisdom on the line every year, meeting head-on the risks of products, prices

and precipitation. Some precision farmers look for future prescriptions of

precisely what to do when. Others expect the development of site-specific

"recipes" to work for more farmers, giving them more latitude to put

their gray cells in charge of the black boxes running their farms--art with

science.

Weather remains the No. 1 variable farmers deal with every day. They

can't control that variable, but they can seek to understand how to plan and

manage variability as a fact of business. As a result, farmers are the

front-line integrators of information and technology. They're turning

information technologies and geographic information systems into geographic

management systems as part of a toolbox of overall farm management tools and

techniques aimed at reducing risk and optimizing efficiency.

This becomes even more important when you consider the future structure

of agriculture. The industry is moving toward consolidation and vertical

integration, along with the adoption of information technologies and

biotechnologies. As a result, there may be fewer farmers. This suggests forward-thinking

producers must forge new links on the farm-to-food chain.

"What you know about what you can grow" will become the key

to farm management. The agricultural industry will become increasingly involved

in planting, growing, harvesting and processing "information" along

with value-added crops.

Site-specific

management drives farmers to accurate record keeping, which will direct their

precision farming decision making. This must be the next transition: from

precision farming to appropriate agriculture--doing the right thing at the

right time in the right place in the right way. At the heart of it all will

remain temporal and spatial decision making--made more effective by GIS working

in tandem with other spatial information technologies.

Yield

Mapping

(Part 3) by Neil Havermale

(Part 3) by Neil Havermale

The GIS-based crop yield data layer is the most important enabling

element in the precision farming revolution. An accurate yield map integrates

nature's climatic effects and a farmer's management decisions. A yield map can

identify natural and manmade variations in a farmed landscape, a crop's genetic

expression in a particular season's environment and more.

There are four general sources of bias in most, if not all, "as

recorded" yield data sets: antenna placement, Global Positioning System

(GPS) latency, instrumentation and modeling errors. Because actual yield is the

basis of future prescriptive action in a site-specific farming system, spatial

accuracy--when tied to a proper model of a combine's threshing

action--determines the final quality of any prescriptive method.

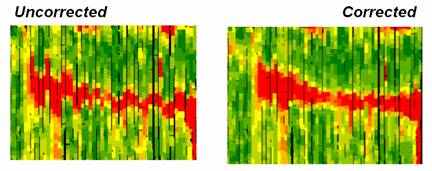

Antenna Offset. Until the last two years, yield monitors

were installed as retrofits on new and old combines. Accurately placing a GPS

antenna on a combine's centerline is critical. With the increasing accuracy of

differentially corrected GPS to within a meter, a foot or two of misplacement

can result in the antenna offset bias pattern shown in the accompanying

figures.

Figure 3. Accurately placing a GPS antenna on a

combine's centerline is critical, as illustrated by an example of uncorrected

(left) and corrected antenna offset (right).

GPS Latency. Latency in various GPS receivers' NMEA

navigation strings has proven to be less than "real time." In fact,

one of the early differentially corrected GPS systems widely integrated into

the leading yield monitor had as much as a 6-8 second latency. The receiver's

latency in this case was directly tied to the differential correction of the

raw pseudo-ranges.

Instrumentation Error. There are two groups of current sensors in

the GPS combine: mass deflection strain gauges and clean grain volume

estimation via infrared beams. A simple examination of the placement of either

of these designs in the combine will reveal that any slope in the field can

easily distort the geometry of the clean grain path of travel. None of the

current yield monitors provide a sensor or correction for instrumentation

failure due to slope.

Model Deconvolution. The modern combine is a marvel. It can

digest literally tons of biomass in an hour, sorting that biomass into clean

grain measured by a grain flow sensor. Material other than grain goes out the

back as chaff. When properly adjusted and operated, the loss of grain out the

back with the chaff will be less than 1%. A combine is a lot like a lawn mower.

It can stall if pushed too quickly into tall, heavy and wet grass, so its

general design has important features that buffer these effects.

Site-specific

farming isn't a new idea. It's as old as childhood stories of Indians showing

pilgrims how to plant corn with fish as a source of fertility. The promise of

modern GIS applications tied to GPS offers users the ability to again

micromanage farming practices--maybe not to a single plant like the pilgrims,

but certainly to 1/100th of an acre. Precision farming systems literally represent

a growing opportunity.

__________________________

Joseph K Berry is principal consultant with Berry &

Associates, Fort Collins, Colorado,

Neil

Havermale, Farmers Software Association, 800 Stockton Ave., Fort

Collins, CO 80524; E-mail: neilh@redhensystems.com.

Grant

Mangold, editor, ag/INNOVATOR,